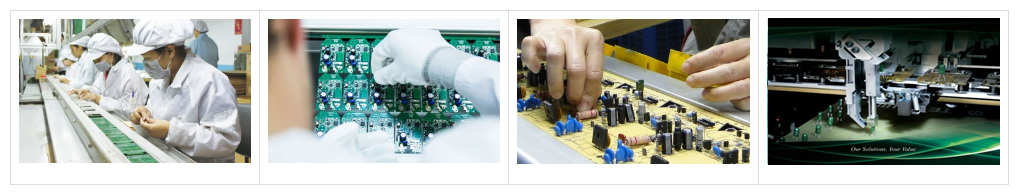

DIP plug-in post welding

DIP plug-in (Dual In line Package), also known as DIP packaging in Chinese, refers to integrated circuit chips packaged in a dual in line form. The vast majority of small and medium-sized integrated circuits use this packaging form, and the number of pins generally does not exceed 100. The CPU chip packaged in DIP has two rows of pins that need to be inserted into a chip socket with DIP structure. Of course, it can also be directly plugged into a circuit board with the same number of solder holes and geometric arrangement for soldering. Special care should be taken when inserting and unplugging DIP packaged chips from the chip socket to avoid damaging the pins. The DIP packaging structure forms include: multi-layer ceramic dual in line DIP, single-layer ceramic dual in line DIP, lead frame DIP (including glass ceramic sealing type, plastic packaging structure type, ceramic low melting glass packaging type), etc. With the rapid development of SMT processing technology, SMT surface mount processing has gradually replaced DIP plug-in processing. However, due to the large size of some electronic components in PCBA production, plug-in processing has not been replaced and still plays an important role in the electronic assembly process. DIP plug-in processing is usually done manually on assembly lines after SMT surface mount processing.

QQ

QQ Skype

Skype Wechat

Wechat